Vacuum Chambers and Custom Fabrication

Our Custom Capabilities

For over 50 years, ANCORP has specialized in the fabrication of high vacuum and ultra-high vacuum (UHV) chambers and components. Our fabricated vacuum chambers range from one-of-a-kind builds for research applications to production quantity chambers for OEM’s.

In 2012, we opened a 6,000 square foot expansion to our factory to meet the growing demand for our Custom Fabrication division. The state-of-the-art facility is equipped with the latest manufacturing technology for CNC mills, lathes, and welding tools.

The expansion includes on-site offices for Engineering and Project Management staff – ensuring you receive the highest quality chamber on schedule. Our welders and Vacuum Welding Program have been certified by AWS and ASME. Our Quality Control procedures include dimensional checks using a Coordinate Measuring Machine (CMM) and leak checks using state-of-the-art helium mass spectrometer leak detectors.

High vacuum and ultra-high vacuum (UHV) chambers are engineered products are engineered products that require a specialized set of materials and fabrication processes. For more information on ANCORP’s capabilities and practices, visit our capabilities page.

Custom Vacuum Chambers

Explore the benefits and recommended applications for each chamber configuration

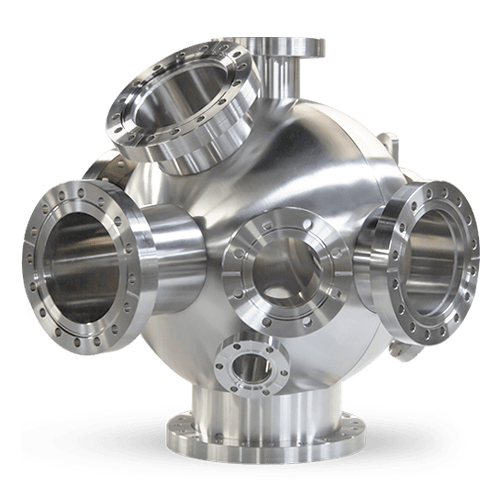

Spherical Vacuum Chambers

Spherical vacuum chambers are specialized chambers with a spherical geometry typically equipped with multiple customizable ports for integrating various sources and analytical instruments.

Benefits

- Radial Component Placement: Spherical chambers allow for precise radial placement of components.

- Optimal volume-to-surface-area ratio: Spherical chambers provide a large working volume, ideal for applications that require substantial space.

- Uniform Concentration: The spherical shape ensures consistent radiation or particle concentration from a single point to multiple focal points.

Applications

- Pulsed Laser Deposition: Spherical chambers are integral to pulsed laser deposition techniques, where the accurate positioning of components along radial lines is essential for optimal results.

- Surface Analysis: Spherical chambers are installed in instruments used for techniques such as X-ray Photoelectron Spectroscopy (XPS), Auger Electron Spectroscopy (AES), Contact Angle Measurements, and Atomic Force Microscopy (AFM).

- Particle/Radiation Source Testing: The multiple ports allow for the introduction and analysis of particle or radiation sources directed at the sphere’s center or other focal points.

For information on specifying spherical vacuum chambers, read our How to Specify a Spherical Vacuum Chamber manual.

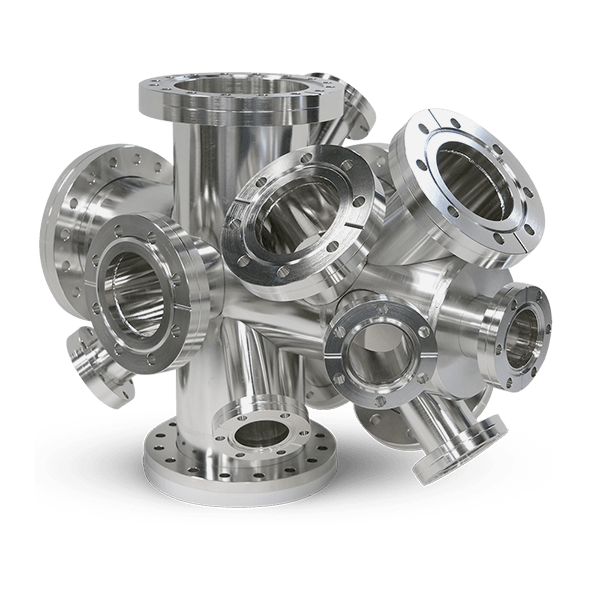

Cylindrical Vacuum Chambers

Cylindrical vacuum chambers are valued for their strength and ease of manufacture. Their cost-effectiveness and ability to maintain high vacuum levels while offering a favorable volume-to-surface area ratio contribute to their widespread adoption.

Benefits

- Cost-effective: Cylindrical chambers are generally less expensive and straightforward to assemble, reducing lead times and costs. The chambers can be fabricated from standard vacuum fittings or custom diameter components.

- Strength: Cylindrical chambers are a robust solution for a wide range of vacuum applications

- Versatile Access Methods: Cylindrical vacuum chambers offer flexibility in access, with horizontal chambers having openings at both ends and vertical chambers providing options such as lifting the base or removing the top lid.

Applications

Semiconductor Industry: Cylindrical vacuum chambers are frequently used in the semiconductor industry, where their strength, volume, ease of manufacture, and ability to withstand high vacuum levels are essential.

- Surface Analysis: Like spherical chambers, cylindrical chambers are also installed in instruments used for techniques such as X-ray Photoelectron Spectroscopy (XPS), Auger Electron Spectroscopy (AES), Contact Angle Measurements, and Atomic Force Microscopy (AFM).

For information on specifying cylindrical vacuum chambers, read our How to Specify a Cylindrical Vacuum Chamber manual.

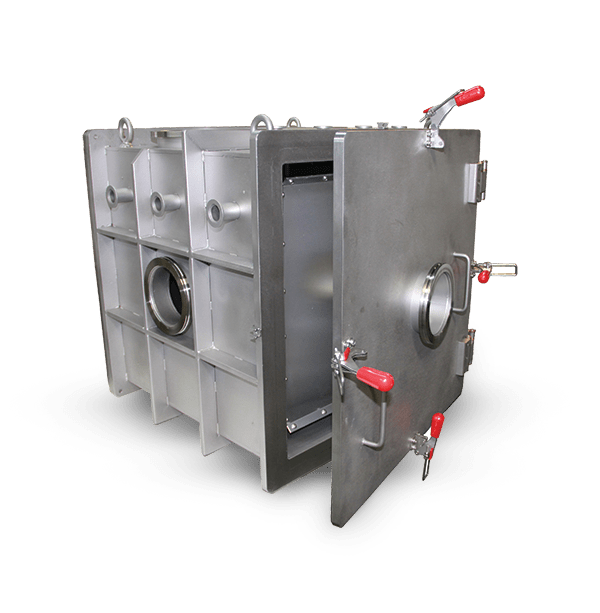

Box Vacuum Chambers

Box vacuum chambers, also known as cubic or rectangular chambers, offer optimal flexibility for accommodating oddly-shaped applications and ensuring swift access to its entire internal volume. Box chambers are ideal for repetitive batch processes or tasks requiring frequent adjustments.

Benefits

- Easy Access: Box chambers provide easy and fast access to any part of the internal volume of the chamber.

- Flexibility for Odd-Shaped Applications: The rectangular shape is conducive to fitting parts that are long, wide, and short.

- Optimal for Repetitive Batch Processes: Box chambers enhance efficiency in repetitive tasks in many applications.

- Adaptable for Research Applications: The ease of access facilitates frequent changes in deposition sources, coating materials, and deposition geometry.

Applications

- Thin-Film Deposition: Box chambers are ideal for depositing thin films on various substrates due to their ease of access and ability to handle large sheets.

- Research Applications: The chambers are beneficial for research tasks where deposition sources, materials, and geometry need frequent adjustments.

Custom Vacuum Components

We offer a variety of custom product types to meet specific needs

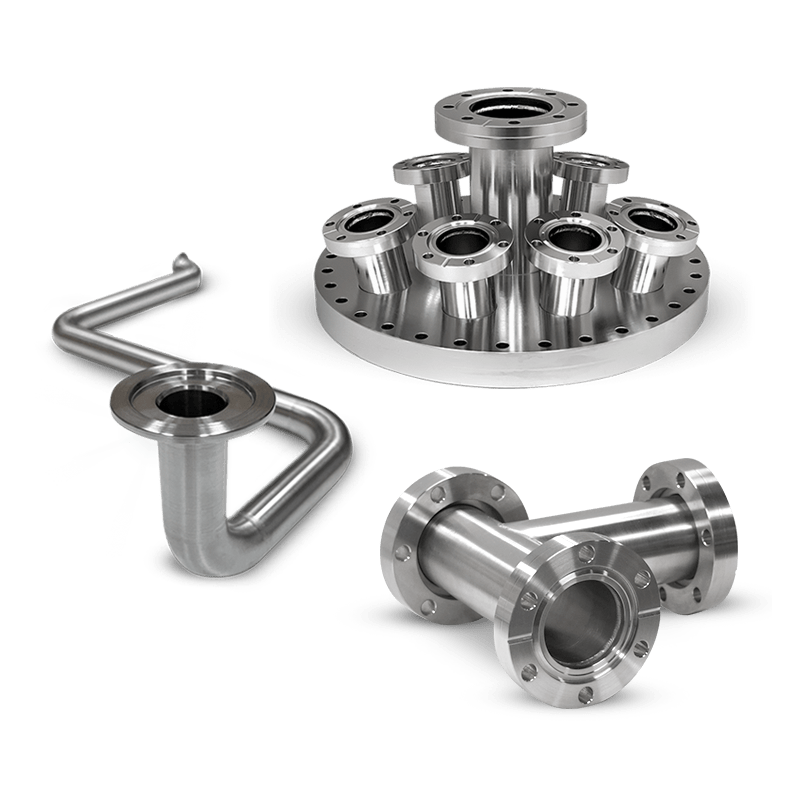

Flanges, Weldments, Spools, Fittings, and More

ANCORP offers a range of custom vacuum products tailored to meet specific needs. These include:

Customized Standard Vacuum Components

Adapt standard vacuum components such as tees, crosses, nipples, and flanges to meet unique requirements, ensuring compatibility and efficiency within specific applications.

Multiport Cluster Flanges

Multiport cluster flanges are flanges designed with multiple ports to facilitate versatile connections and are customized to integrate seamlessly into any vacuum system. Multiport flanges are crucial for UHV and XHV systems that necessitate the integration of multiple process components like viewports, pressure gauges, and sputter sources on a single chamber. The versatility in flange size and configuration enables users to optimize system connections, especially in space-constrained settings. View our standard offering of multiport flanges here.

Weldments and Spools

Custom weldments and spools are meticulously fabricated to guarantee leak-tight assemblies, seamlessly connecting various sections of a vacuum system while ensuring a secure seal and uninterrupted flow.

These products are meticulously designed and crafted to cater to specialized demands, thereby ensuring optimal performance in vacuum systems.

Previous Custom Projects

Check out our Instagram feed for custom products we've manufactured for previous projects

Titanium and Aluminum for UHV and XHV Chambers

Enhanced Bakeout Performance and Reduced Outgassing Rates

As the exclusive seller and distributor of LOS Low Outgassing Solutions products, ANCORP provides our customers custom ultra-high vacuum (UHV) and extremely high vacuum (XHV) chambers with titanium and aluminum bodies. Aluminum and titanium offer UHV and XHV applications enhanced bakeout performance and lower outgassing rates compared to their stainless-steel counterparts.

Aluminum and Titanium also provide end-users higher vibrational dampening than stainless steel due to the materials’ young’s modulus. This higher vibrational dampening greatly benefits applications requiring precision in targeted instrumentation. Both titanium and aluminum chambers also have thermal conductivity coefficients several magnitudes greater than stainless steel enabling faster bakeout times. Additionally, these materials feature less hydrogen in the alloy structure contributing to decreased outgassing rates.

Titanium

- Low Z attribute

- Negligible magnetic permeability

- 25% higher yield strength than 6061-T6 aluminum

- Lower outgassing rate than stainless steel

- Lower vibration damping than stainless steel

Aluminum

- Fast uniform bakeouts

- Bakeouts at 150 degrees Celsius

- Increased thermal diffusivity

- Lower outgassing rate than stainless steel

- Lower vibration damping than stainless steel

Engineering and Project Support

From your initial inquiry to when your finished vacuum chamber ships out of our factory.

ANCORP engineers and project support staff are working to ensure your custom project meets your highest quality standards and is delivered on schedule. Before manufacturing begins, engineers trained in vacuum technology and chamber design review design drawings. Project support staff ensures the manufacturing schedule is kept and drawing specifications and tolerances are met. ANCORP can work with customer-supplied drawings or create drawings from simple, freehand sketches.

Let's Get Started

Start by submitting a quote for your custom project.

You can submit your quote through our request a quote form or by contacting a member of our technical sales team. Quotations can be generated from simple, freehand sketches. Electronic files can be sent in a variety of file formats. When needed, ANCORP can supply a complete set of engineered drawings.