Multiport Valves

ANCORP’s Multiport valve is a 1.5” high vacuum valve designed for 3-way, 4-way, or 5-way flow in demanding semiconductor and coating processes. Its modular design and configurable components enable a variety of flow patterns through the valve.

The Multiport valve consists of a cube-shaped valve body, a fully stabilized Extended Life (XL) valve stem, a fully ported ball, and end caps (body ports), all machined from corrosive-resistant 316L stainless steel. Flanged body ports or blank end caps are installed on the sides or bottom of the valve body to create a 3, 4, or 5-way valve. An L-port, T-port, or other ported ball rotates within the valve to switch flow between body ports.

FKM or FFKM O-rings seal the valve stem and end caps from atmosphere while PTFE valve seats cold flow around the ball to seal the desired body port(s) from the other body ports. The PTFE sealing surfaces are protected from direct deposition or contact with process matter, maintaining a clean, dynamic seal to prevent failure due to contamination.

Features and Benefits

- Patented Extended Life (XL) valve stem – stabilized stem seal eliminates atmospheric intrusion into the process line and provides high cycle life and reliable high temperature performance with FFKM O-rings

- Fully ported ball – maximum conductance with no restriction in flow path reduces particle buildup

- Evac holes on ball and blank end caps – valve interior always under vacuum, prevents virtual leaks

- Recessed fasteners and flat surfaces – improved heat transfer from heater jacket

- Faster servicing – valve stem housing can be swapped out in the field

- ISO 5211 mounting pattern – compatible with all modern valve actuators

- NAMUR VDI/VDE 3845 compliant stem detail – compatible with all modern valve position indicators

Specifications

- Standard flanges: QF40

- Standard ball types: L-Port, T-Port, Vertical L-Port, Vertical T-Port, Double L-Port, Double T-Port

- Actuation: Manual or pneumatic

- Vacuum and Temperature Ratings

- Vacuum rated to 1 X 10-8 Torr

- Helium leak rated less than 1 X 10-9 std. cc/s

- Standard fluoroelastomer (FKM) seal: -26°C to 150°C (-15°F to 302°F)

- Materials

- Valve body, ball, stem, and end caps: machined from solid 316L stainless steel

- Standard seal: fluoroelastomer (FKM)

- Seats: PTFE

- Lubricant: Dow Corning®/DuPont Molykote High Vacuum Grease

- Pneumatic

- Actuator operating pressure: 80 – 120 psig

- Actuator temperature range:

- Moist air: 0°C to 150°C (32°F to 302°F)

- Dry air: -20°C to 150°C (-4°F to 302°F)

- Spring return actuators and double-acting actuators are available

- 1/8 NPT air line hook-up

- Visual and electrical position indicators available

- Solenoids available for 120VAC or 24VDC versions

- Custom Options

- Contact us for custom options including centerlines, vacuum grease, position indicators, and o-rings.

Downloads

- Multiport Valves Brochure (PDF)

- CAD Models and Drawings:

- Reference Number: 1MP150-3H-QF40XQF40XQF40-S-M1-T1

Description: 1.5″ Multiport Ball Valve, 3H Body, QF40 Flanges, Standard, Manual Actuation Position 1, T-Port Position 1- PDF: 3300008a.pdf

- CAD: 3300008a.stp

- Reference Number: MP150-3H-QF40XQF40XQF40-S-AA1-T1

Description: 1.5″ Multiport Ball Valve, 3H Body, QF40 Flanges, Standard, Air-to-Air (AA) Actuation Position 1, T-Port Position 1- PDF: 3300016a.pdf

- CAD: 3300016a.stp

- Reference Number: MP150-3H-QF40XQF40XQF40-S-AS1-T1

Description: 1.5″ Multiport Ball Valve, 3H Body, QF40 Flanges, Standard, Air-to-Spring (AS) Actuation Position 1, T-Port Position 1- PDF: 3300020a.pdf

- CAD: 3300020a.stp

- Reference Number: 1MP150-3H-QF40XQF40XQF40-S-M1-T1

Applications

The corrosive-resistant, fast-actuating design of ANCORP’s multiport valve makes it ideal for diverting, switching, combining, or splitting flow in and around reactors, traps, scrubbers, and exhaust lines on vacuum coating, etch, and abatement tools.

With a fully ported ball and minimally wetted internal components, the multiport valve resists particulate buildup and valve contamination in harsh or dirty downstream environments. 3-Way, 4-Way, and 5-way multiport valves can replace multiple 2-way valves and additional fittings on vacuum lines and manifolds.

Multiport Valve Configuration

The Multiport valve’s modular design allows for six body port configurations and six ball configurations. Body ports, ball ports, ball position, and actuation type can be specified to enable a variety of flow switching, diverting, or mixing operations between source and destination ports.

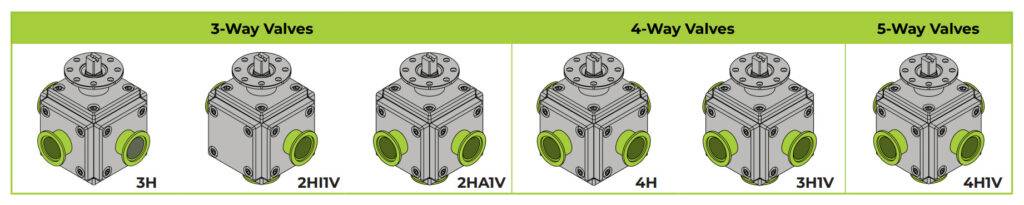

Body Port Configurations

Body ports or blank end caps can be configured on the sides and bottom of the valve body to make a 3, 4, or 5-way valve.

Three Way Valve

3-way valve body port configurations include 3H (3 ports in a horizontal orientation), 2HI1V (two horizontal inline ports with one vertical port on the bottom face), and 2HA1V (two horizontal ports at an angle with one vertical port on the bottom face).

Four Way Valve

4-way valve configurations include 4H (four horizontal ports on all side faces of the valve) and 3H1V (three horizontal ports with one vertical port on the bottom face).

Five Way Valve

A 5-way valve configuration, 4H1V, has body ports on all faces of the valve (four horizontal ports with one vertical port on the bottom face).

Ball Port Configurations

Ball types include L-port, T-port, vertical L-port (VL), vertical T-port (VT), double L-port (LL), and double T-port (TT). Standard L-port and T-port balls have ports oriented horizontally for use with 3-way or 4-way valves with no vertical bottom port. Vertical L-port, vertical T-port, double L-port, and double-T port valves have both horizontal and vertical ball ports for use in multiport valves with vertical body ports on the bottom face of the valve.

Actuation

The valve can be actuated manually or pneumatically. Manual valves can be actuated by turning the handle in 90° increments, with full 360° rotations possible.

Spring return actuators use compressed air to turn the ball 90° counterclockwise, and spring forces to rotate the ball 90° clockwise back to its starting position. In the event the actuator loses air pressure, the springs will rotate the valve back to its starting position. For that reason, these actuators are often referred to as fail-safe actuators.

Double-acting actuators use compressed air to cycle the valve 90° counterclockwise as well as to cycle the valve 90° clockwise back to its starting position. The valves can be customized with other actuation methods, such as electrical actuation or 180° pneumatic actuation, upon request.

The position of the actuation device, whether manual or pneumatic, can be specified to avoid interference problems in tight spaces and allow for the convenient connection of air lines.

Allows for easy rotation in 90° increments

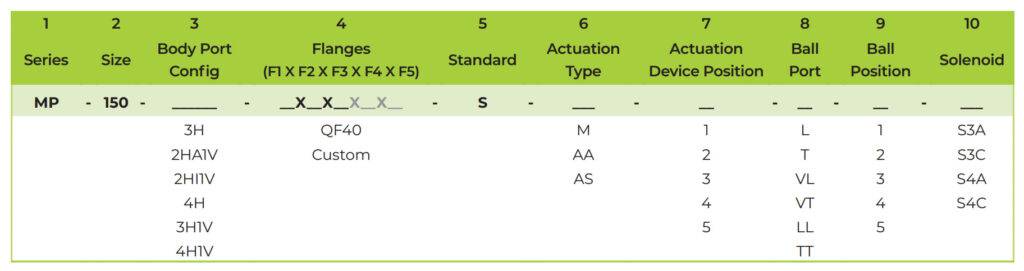

Standard Reference Number Configurator

Use the configuration table below to build your Multiport valve Reference Number.

Configurator Notes

4. Flanges

- Flange 1 (F1) is defined as the flange with the most successive clockwise flange neighbors. If there are equivalent clockwise neighbors, naming is arbitrary. Flange 2 (F2) is the next clockwise flange from Flange 1, and so on.

- When a vertical body port is present, it will be assigned the last flange number.

- Blank end caps will be numbered such that the next unused flange number (4 or 5) will be applied to the end cap immediately clockwise from the last horizontal flange number. I.E., number the flanges, then number the end caps.

- A blank bottom cap is not numbered.

6. Actuation Type

- Pneumatic actuators rotate counter-clockwise from their default, unenergized state.

7. Actuation Device Position

- The actuation device position is defined by the flange or end cap number to which either the valve handle or the actuator air inlet/cable entry is aligned.

8. Ball Port

- The primary ball port is the horizontal port with its axis perpendicular to the ball’s stem slot and with the most successive clockwise port neighbors. If there are equivalent clockwise neighbors, naming is arbitrary.

9. Ball Position

- The ball postion is defined by the flange or end cap number to which the primary ball port is aligned in the valve assembly’s default state.

Let's Get Started

Start by submitting a quote for your multiport valve.

You can submit your quote through our request a quote form below or by contacting a member of our technical sales team.

For more information on Multiport valves, download our brochure here: