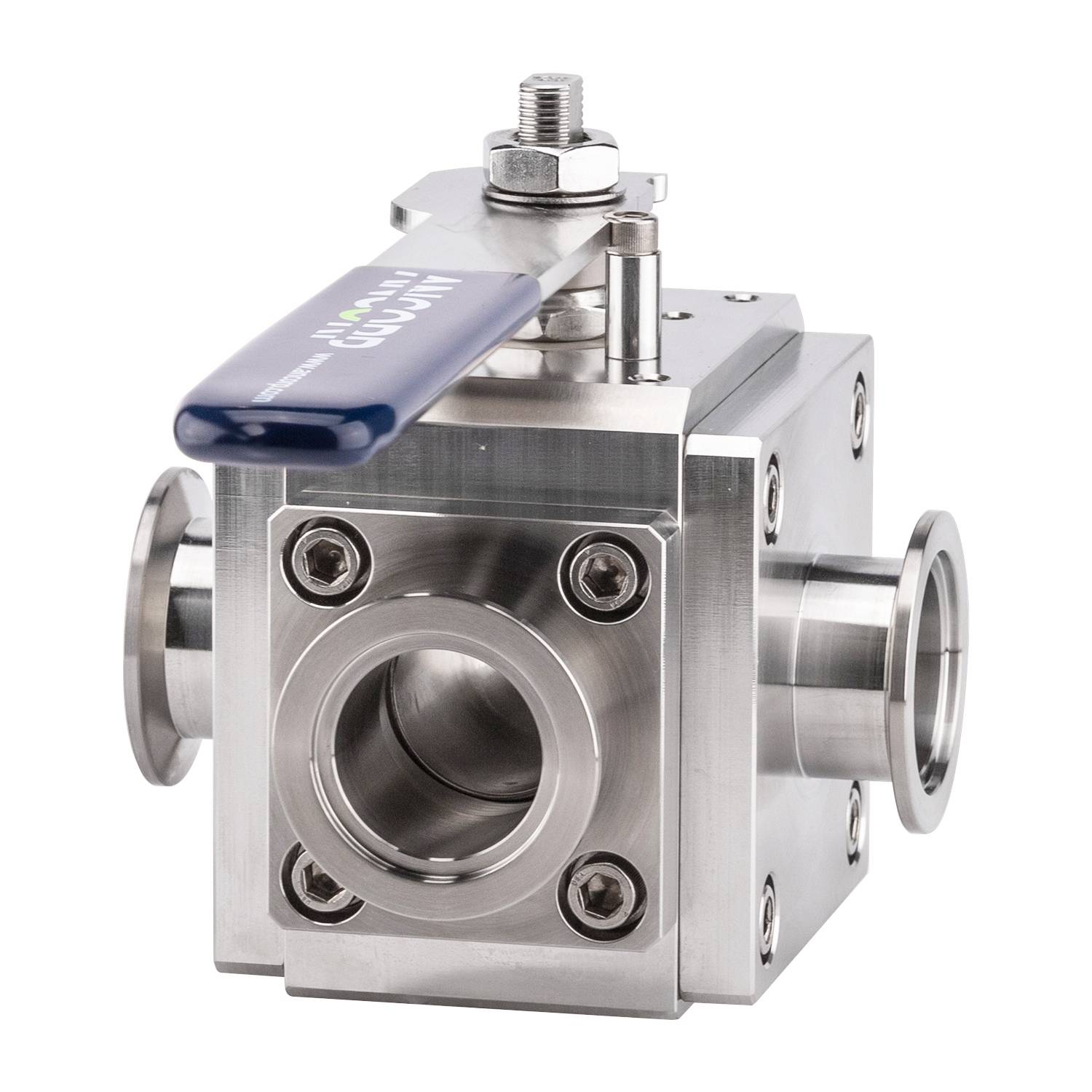

3-Way Ball Valves

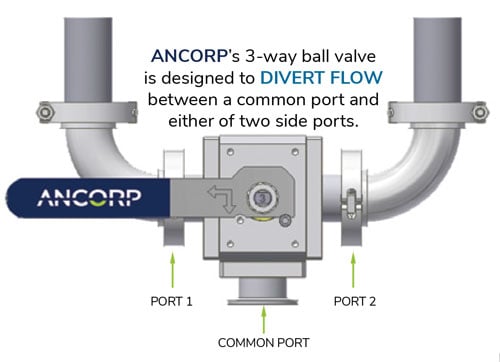

ANCORP’s 3-way ball valve is designed to divert flow from either of two inlet ports to a single, common outlet port. The 3-way ball valve consists of a body, stem, L-port ball, and three end caps. Components are machined from corrosive resistant 316L stainless steel. Fluoroelastomers are used to seal the stem and end caps from the atmosphere while Teflon® seats cold flow around the ball to isolate one outlet port while diverting flow through the other. Flow through the valve is diverted manually or pneumatically by 1/4 turn, quick actuation. The Teflon® sealing surface is protected from deposition, maintaining a clean dynamic seal that prevents failure due to contamination. This feature reduces particulate build-up, making this valve robust in particle-rich effluent streams.

Applications

The corrosion resistant design of ANCORP’s 3-way vacuum ball valves makes them ideal for diverting flow or isolating pumping lines, reactors, traps, and scrubbers on vacuum coating tools used for MOCVD, PVD, and other thin-film coating processes.

Features

ANCORP’s 3-way ball valve maximizes design efficiencies in high vacuum systems and coating tools when compared to multi-valve systems with equivalent functionality:

- Reduced bill of materials

- Reduced footprint

- Reduced overall weight

- Reduced design complexity

- Fewer actuated components

- Fewer leak paths

- Less total area to heat

- Reduced maintenance costs from MRO parts