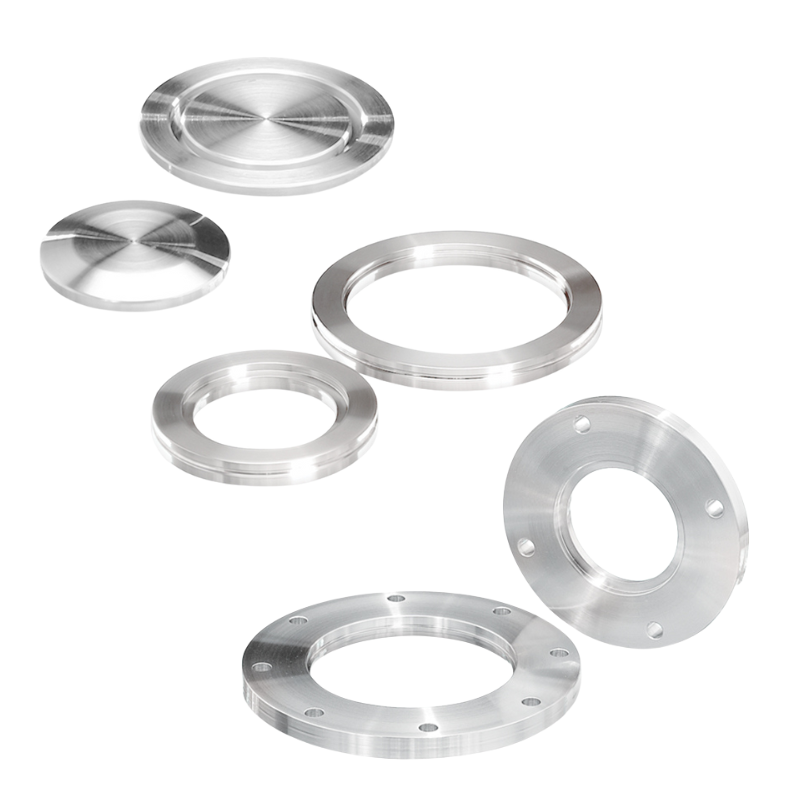

Vacuum Flanges

Vacuum flanges are the connection points that keep your system together. These components are found at every joint across your vacuum system, offering leak-tight sealing for every connection. Flanges can be bored with a central opening or blank with no bore, with options for efficient sealing across all vacuum levels.

Selecting the correct flange system for your process is crucial to achieving optimal performance, longevity, safety, and serviceability. Factors such as operating temperature, cleanliness requirements, chemical compatibility, and maintenance windows will affect which flange style is compatible with your vacuum system. With specific solutions tailored for every application need, you can browse ANCORP’s range of high vacuum flanges with confidence.

ASA Flanges

Sealing for Rough to High Vacuum

ASA or ANSI vacuum flanges are named for the American Standards Association or American National Standards Institute. This system is designed with sexed, rotatable-fixed flange pairings to handle vacuum ratings up to 1×10-8 Torr. The sealing assembly consists of two flanges, an elastomer O-ring, a bolt fastener kit, and an insert and housing on rotatable flanges. This flange assembly is designed for vacuum users with in-house welding capabilities, as the insert is welded onto the tubing following the placement of the rotatable housing.

ASA flanges are bolt-together flanges commonly used in industrial vacuum applications where ultra-high vacuum performance is not necessary. Since they seal using O-rings, they are best suited for systems operating in the rough to high vacuum range. Known for their mechanical strength and straightforward assembly, ASA flanges are often found in large vacuum chambers, vacuum furnaces, and general-purpose industrial systems where robust connections are a priority.

ConFlat Flanges

Metal Sealed for UHV Applications

CF flanges are the industry standard for vacuum systems operating in the ultra-high vacuum (UHV) range. Widely used in fields such as semiconductor manufacturing, surface science, and particle physics, CF flanges provide the reliable vacuum integrity required for sensitive and demanding UHV applications.

Part of the UHV system preparation process requires a vacuum bakeout, an extremely high-temperature procedure designed to burn off residual contaminants. When equipped with traditional metal seals, CF flanges can withstand bakeout temperatures up to 450°C. CF flanges are available in 304L SS or 316LN SS with outer diameters from 1.33” to 16.5”, making them versatile for a wide range of system connections.

ConFlat flanges are also a sexless design. This allows for rotatable and fixed pairings without the need to ensure mating orientation, as both inner faces of the flange bite into the gasket to form a reliable, leak-tight seal.

ISO Flanges (KF, ISO-K, ISO-F)

Modular Connections for Systems in High Vacuum

ISO vacuum flanges are manufactured to the International Standard of Organization 2861 standards and tolerances. They are an economical, convenient, and simplified means of constructing vacuum systems. The family of flange connections includes a variety of sealing methods such as KF (QF), ISO-K (ISO-LF), and ISO-F (ISO-LFB), all operating in the 1 x 10-8 Torr range.

The range of sealing methods within the ISO system accommodates multiple clamp and bolt assemblies, positioning it as a convenient and simplified means of connecting systems. Further, all ISO styles rely on elastomer O-ring sealing for easy and repeatable assembly. This combination positions ISO flanges as ideal for systems requiring frequent access or reconfiguration.

Wire Seal Flanges

Large Diameter UHV Applications

Wireseal flanges offer many of the same benefits as the CF system and are most commonly used for applications requiring flanges larger than those available with CF. Wire seal flanges are sexed, resulting in male and female flanges. Much like their CF counterpart, wireseal flanges are suited for applications in nuclear research, space simulation chambers, and particle accelerators. ANCORP’s Wireseal flanges accommodate inner tube diameters from 17” to 25”.