Vacuum Coating and Deposition

Vacuum Coating and Deposition

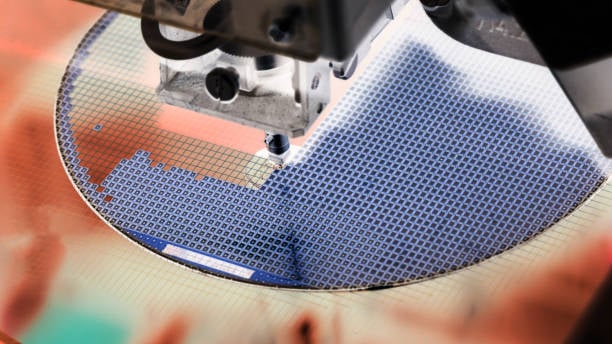

Over the last 20 years, old methods of coating processes have been replaced with more efficient, and more cost-effective thin film coating techniques.

ANCORP products are found in systems that our customers use for sputter deposition, evaporation, ion-assisted deposition, atomic layer deposition and more to produce consumer goods, mirrors, lenses, storage devices, and industrial coatings.

ANCORP supplies ball valves, custom fabricated components, and vacuum hardware to end-users who utilize Chemical Vapor Deposition (CVD) and Physical Vapor Deposition (PVD) around the world. With these components, researchers and manufacturers have the ability to create low pressure and “clean” vacuum environments to produce products with complete flow control on pressure and gas volumes.

Investing time and resources into product development and improvement is at the core of providing solutions for our customers. With that focus in mind, our products serve to improve efficiency, refine processes, and help industrial equipment manufacturers make a product that lasts.

Modern manufacturing and research rely on high-performance thin films to improve product functionality, durability, and appearance. ANCORP components are found in systems performing a wide range of deposition techniques including sputter deposition, evaporation, ion-assisted deposition, and atomic layer deposition (ALD). These processes are core to building up nanoscale layers that form the basis of microelectronic devices, sensors, wear-resistant surfaces, and more.

High Conductance Ball Valves

Built for processes like sputtering and evaporation, our high conductance ball valves support the integration of heating components and maximize flow—ideal for systems where throughput, uptime, and flow uniformity matter. They feature a unique, quick shut-off solution putting you in control of gas and vapor flow.

Viewports and Shutters

Designed for use in PVD and CVD chambers, ANCORP viewports offer clean optical paths across a wide range of materials and permeable wavelengths. Shutters then serve as a critical safeguard for these viewports, designed to prevent material deposition on the viewport glass, ensuring window cleanliness.

Custom Vacuum Chambers

Custom chamber designs provide thermal uniformity, specialized access ports, and integration points for source material, substrate holders, or cryogenic lines.

Vacuum deposition is integral to the development of next-generation energy technologies. Battery and fuel cell research use thin film deposition to create stable electrodes, barrier layers, and conductive coatings that enhance efficiency and longevity. Solar photovoltaic cells also rely on depositions to create uniform coatings with high purity and repeatability within solar energy generation.

ConFlat Flanges and Fittings

For thermal stability and sealing under UHV, ConFlat hardware is essential. ANCORP offers 304 and 316L stainless steel CF flanges and fittings to support high-temperature CVD systems and material deposition on substrates.

Up-to-Air Valves

ANCORP’s up-to-air valves provide a reliable way to safely vent a vacuum chamber to atmosphere or backfill it with a gas of your choice. Commonly used in energy applications, such as metal-organic chemical vapor deposition (MOCVD) systems, these valves help ensure controlled chamber cycling and process stability.

The advancement of modern optics and photonics is made possible by vacuum-enabled coating technologies. Thin film coatings applied in vacuum environments enhance the way light interacts with optical components, enabling high-precision processes across research, manufacturing, and defense.

Processes like photolithography, laser materials processing, metrology, and optical sensing depend on anti-reflective layers, beam splitters, dielectric mirrors, and wavelength-specific filters, all created using vacuum deposition methods such as Physical Vapor Deposition (PVD) and Ion-Assisted Deposition (IAD).

Optical-Grade Viewport

Engineered for beam delivery and observation, our viewports are used in systems for photolithography, laser processing, and sensor alignment. We have a wide variety of materials and coatings that offer comprehensive wavelength coverage.

ConFlat Multiport Flanges

ConFlat (CF) flanges are the standard for UHV sealing, offering reliable, leak-tight metal seals that can withstand high bakeout temperatures and maintain vacuum integrity over time. Multiport CF Flanges offer these benefits in addition to multiple access points within a single flange for integrating lasers, sensors, and viewport optics in multi-axis alignment in photonic systems or beamline research.

Vacuum Valves

Our vacuum valves selection is known for clean performance and robust sealing under repeated cycling. Quality flow control minimizes pressure spikes and potential contamination pathways that can degrade mirror and lens coatings.