Aerospace

Vacuum in Aerospace

Providing reliability for the most demanding environments

From orbit to operations, ANCORP’s high and ultra-high vacuum components play a critical role in advancing aerospace and defense capabilities. Our engineering and manufacturing expertise supports national laboratories, military branches, and private space innovators all with unique requirements for precision, reliability, and performance. Whether enabling mission-critical testing environments or providing components for cutting-edge deposition systems, we design for durability under extreme thermal, vibrational, and vacuum conditions. As a U.S.-based manufacturer, we take pride in delivering vacuum solutions that meet the stringent demands of modern aerospace programs and national defense infrastructure.

Aerospace

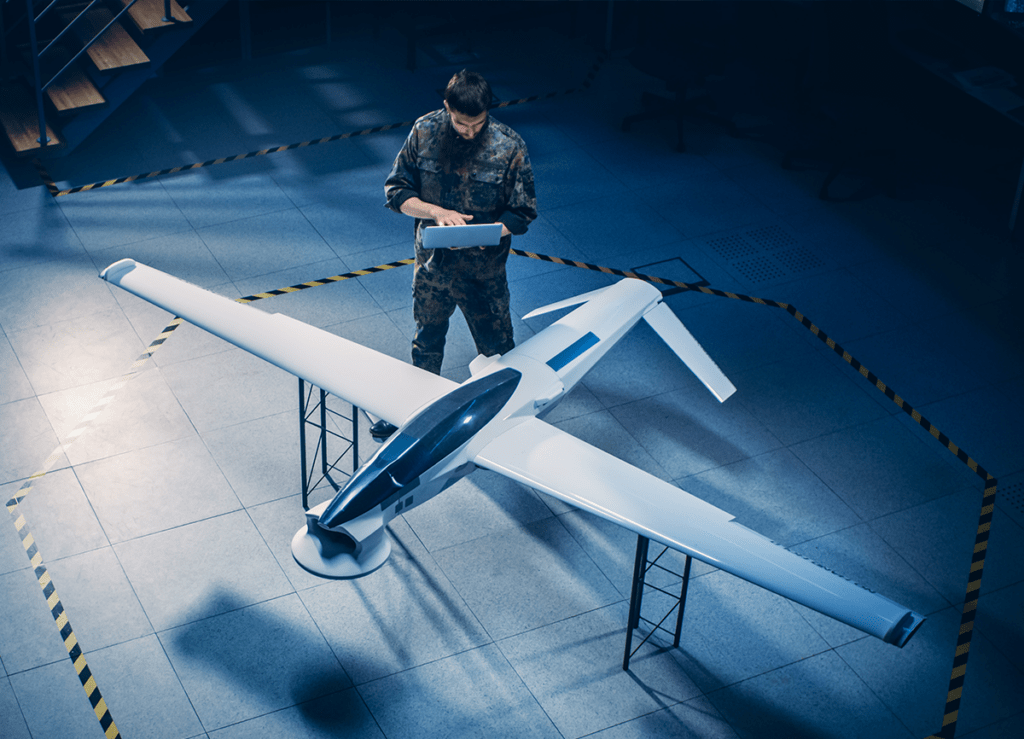

ANCORP solutions for the aerospace industry are manufactured to endure the thermal and vibrational stresses present in the environmental conditions of both atmosphere and space. Our customers are often recreating space simulations within their custom chamber system and making depositions and coatings on new technologies that must withstand extenuating forces. With a large variety of high and ultra-high vacuum products, we help private and public aerospace companies empower the future of spacecrafts, national defense systems, and instrumentation.

Simulating Space for Validating Mission Critical Components

Vacuum systems engineered for space simulation must replicate the harsh environmental conditions of outer space to properly validate components for mission use. Reproducing conditions found in space such as radiation exposure, deep vacuum, and extreme thermal cycling requires ultra-clean vacuum environments, precision temperature control, and the ability to integrate a wide range of test instrumentation. Through simulations, components can become validated for use in applications such as navigation systems, space telescopes, spacecraft instruments, and planetary rovers.

Vacuum Chambers

ANCORP stainless steel vacuum chambers provide the structural and vacuum integrity required for thermal vacuum testing. Available in box, cylindrical, or spherical configurations, these chambers support integrations such as thermal shrouds, LN₂ cooling lines, and radiant heater arrays. Their customizable flange layouts enable direct interfacing with test fixtures, sensors, and monitoring systems to replicate orbital day/night cycles, deep space exposure, or lunar surface conditions.

Vacuum Viewports

Viewports made from specialized materials and coatings allow optical access for monitoring spacecraft behavior during test sequences. They are mounted using CF or ISO flanges to ensure leak-tight integration into the vacuum vessel; however, a CF attachment is recommended to accommodate for the ultra-high vacuum conditions in replicating space conditions.

Rotary Motion Feedthroughs

Rotary feedthroughs allow simulation systems to move or rotate spacecraft components while maintaining vacuum. These are critical in thermal vacuum chambers where antenna alignment or the ability to make mechanical adjustments must be tested under vacuum. Depending on your system and torque requirements, a ferro-sealed motion feedthrough may be preferred over a elastomer-sealed rotary feedthrough

Aluminizing

Aluminizing is a vacuum-based surface treatment that deposits evaporated aluminum onto stainless steel within a high vacuum environment. This process creates a final material with an outer layer that is higher in corrosion resistance and exhibits much more effective heat transfer than unprocessed stainless steel. As a result, aluminized steel is commonly used for turbine blades, exhaust components, and structural elements exposed to extreme thermal and oxidative environments.

ISO-QF (KF) Flanges and Fittings

ISO and KF flanges and fittings are ideal for serviceable connections on aluminizing setups, particularly for peripheral devices like gas injectors or vacuum sensors. As they function in the high vacuum range, including them in aluminizing assemblies makes them a strong fit for coating rigs or systems needing routine cleaning or process changeovers.

Vacuum Valve

Across the wide range of vacuum valves, ANCORP’s control and isolation valves are most practical for the aluminizing process. Isolation valves enable the separation of sections within a vacuum system, important for compartmentalizing differing procedures within a system. Control valves create the ability to introduce specified flows of vaporizing gasses, such as aluminum vapors, for diffusion onto a surface.

Electrical Feedthroughs

ANCORP electrical feedthroughs are hermetically sealed to form a vacuum ready electrical pathway between atmospheric and vacuum sides of a system. This allows for compatible electrical components to power internal heating elements required in the aluminizing process.

Vacuum Brazing

Vacuum brazing is a metal joining process that uses a filler metal to bond components at high temperatures in a vacuum environment. Because this process occurs in vacuum, the joint is protected from potential oxidation and contaminants resulting in a high-integrity bond. This technique is widely used to create high-quality aerospace components for assembling heat exchangers, fuel systems, and structural assemblies, ensuring strong, leak-free joints.

Vacuum Chambers

The environment for vacuum brazing is protected by a robust vacuum chamber that will encompass the joining process. The benefits of a customized vacuum chamber is the ability to choose custom geometries (box, cylindrical, or spherical) and specify dimensions for unusually shaped or large components. Commonly made from stainless steel, high-quality vacuum chambers are engineered to support repeatable brazing cycles and maintain heat temperature uniformity.

Pneumatic Vacuum Valves

Pneumatic valves support the rapid actuation required for multi-stage thermal cycles in the brazing process. The right valve will withstand repeated thermal stress and contribute to higher throughput and require less maintenance to improve system uptime. With reliable switching, a pneumatic vacuum valve provides peace-of-mind through the pump-down, heating, and venting stages of brazing.

ISO-QF (KF) Flanges and Fittings

ISO flanges and fittings facilitate modular connections in vacuum brazing systems, allowing for flexibility and ease of maintenance. The O-ring seals in the flange assemblies provide reliable performance in the medium to high-vacuum range typical of aerospace brazing applications, while clamp-style and bolt-style interfaces support flexibility in system design.

Vacuum Heat Treatments

Vacuum heat treatment is a thermal process used to enhance the mechanical properties of aerospace components, such as strength, ductility, or dimensional stability. Unlike aluminizing or brazing which affects the surface of components, vacuum heat treatments transform the material itself by altering its microstructure. This makes vacuum heat treating ideal for critical components such as landing gear, turbine shafts, and structural frames that must meet demanding fatigue and load-bearing requirements.

ConFlat (CF) Flanges and Fittings

CF flanges are ideal for the high-temperature environments of vacuum heat treatments. Their all-metal seal design features oxygen-free copper gaskets ensuring reliable, leak-tight connections throughout extended heating cycles. This makes Conflat flanges the preferred choice in heat treatment systems where vacuum stability must be maintained at elevated temperatures and during repeated bake-outs.

Control and Isolation Valves

Valves are essential for managing the chamber environment during the different stages of a heat treatment cycle. ANCORP’s isolation and control valves support repeatable process conditions, enabling fine adjustments to vacuum level and gas backfills when required. Available with CF flange connections, the right valve will resist thermal and mechanical stress, ensuring consistent performance over numerous heat treatment runs.

Advanced Propulsion Development

Propulsion testing chambers are used to validate chemical, ion, or Hall-effect thrusters under vacuum. Such testing environments are essential for qualifying thrusters used in satellite maneuvering, deep-space propulsion, and emerging in-space transportation platforms. Vacuum systems used in propulsion development are used to confirm thrust performance, power draw, propellant flow, and material compatibility for large and small propulsion systems. These applications require robust hardware that supports electrical isolation, gas injection, and high-throughput pumping—all without compromising vacuum performance.

Weldable Components

Propulsion test chambers often require custom fixtures to accommodate exhaust beam dumps, gas injection manifolds, or thrust stands. ANCORP’s weldable half-nipples, adapters, and metal bellows provide a foundation for securely fabricating structures. These weldable components allow propulsion engineers to build durable, custom infrastructure with precise dimensional control.

Vacuum Feedthroughs

Feedthroughs are essential for enabling internal actuation, electrical power, and fluid transfer within propulsion test chambers while maintaining vacuum integrity. Our feedthroughs support electrical connections for powering thrusters and sensors, rotary motion for actuating or gimbaling propulsion units, and fluid/gas feedthroughs for managing propellants or circulating cryogenic coolants to simulate in-space thermal conditions.

VAT Gate Valves

Gas delivery systems for propulsion tests require moving large volumes of gas in a way that maximizes conductance and minimizes the load on the vacuum system. VAT gate valves are ideal for routing gasses to pre-heaters, regulators, or injectors, offering flow control and fast-acting shutoff. Their reliability and sealing performance help maintain system integrity under demanding test conditions.