Dirty, particle-rich environments such as those found in vacuum coating and deposition systems frequently encounter problems with buildup and restricted conductance when regulating flow with isolation valves. Traditional industry valve solutions offer bulky designs without addressing the design features contributing to these issues.

At ANCORP, we’ve designed a high conductance ball valve to address these challenges for large-diameter vacuum lines in high particulate vacuum environments.

While other system applications may have different contamination allowances, vacuum coating and deposition techniques such as PVD, CVD, ALD, and sputtering all rely on a careful balance of gas flow, vacuum level, and temperature for proper operation. Every component in the system plays a role in achieving that balance including valves.

A large part of this optimization dials in on conductance.

Choosing components that maximize conductance can be the difference between a system that struggles with efficiency and one that consistently delivers high-quality results. It directly influences pumping speed, pressure stability, and process performance.

An effective way to maintain good conductance in a vacuum line is with the use of a high conductance (HC) ball valve.

What is a High Conductance Ball Valve?

A high conductance ball valve is a specialized isolation valve engineered to minimize flow resistance and particle buildup.

Available in sizes up to 4 inches for large-diameter piping, the high conductance valve builds on the foundation of ANCORP’s iconic standard ball valve while introducing a specialized design for applications where conductance is a priority.

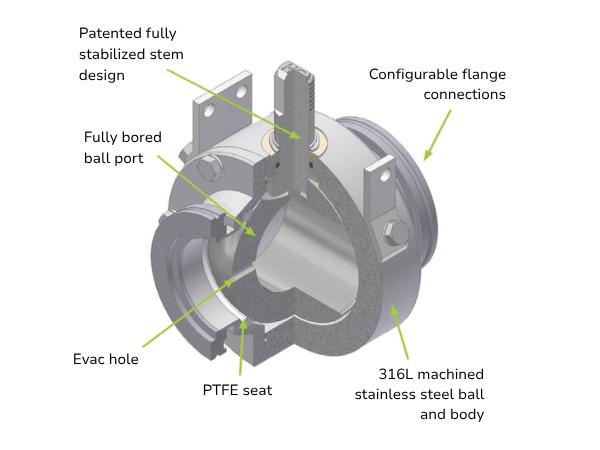

Like ANCORP’s standard ball valves, HC valves are built with a robust body, stem, ported ball, and flanged end caps. They also come equipped with the patented Extended Life Seal, which provides long-lasting, reliable performance under vacuum conditions.

What sets our high conductance valve design apart? This valve has been thoroughly engineered with precise dimensional adjustments that improve conductance, minimize resistance, and simplify maintenance. These designs include…

- Fully bored ball port – creates an unimpeded, straight-through channel that maintains diameter and maximizes flow.

- Reduced body length – shortens the flow path, minimizing resistance in line with the conductance formula.

- Smooth internal contours – eliminates abrupt transitions that would otherwise create turbulence or cold spots, improving both flow and heat transfer.

- Two-piece body – one less potential leak path & huge maintenance cost reductions when using perfluoroelastomers.

- Smooth profile – maximizes heat transfer from heating components.

How do High Conductance Valves Optimize Conductance?

By reducing the body and redesigning the internal flow path, high conductance ball valves create a straighter, more direct channel for gas molecules to pass through. This results in improved conductance, making it an essential optimization for coating and deposition systems where flow efficiency is critical.

With two-piece valve construction, we have reduced the number of potential leak paths within the valve. Through one less body O-ring seal, leak potential is reduced, and you can benefit from huge reductions in perfluoroelastomer maintenance costs.

By improving these factors, high conductance valves enhance molecular flow and through geometry.

In simple terms, with conductance describing how easily gas molecules move through a part of the vacuum system, we’ve optimized the valve completely to maintain flow as easily as possible. This directly supports faster pump-down times, more stable chamber pressures, and higher throughput in coating and deposition processes.

Why Conductance Matters in Coating and Deposition

Vacuum coating and deposition are challenging environments where residual particulates, condensable vapors, and film buildup demand careful contamination and maintenance control. In these systems, maximizing conductance has several direct benefits:

- Process efficiency – faster pump–down time and cycle times translate to higher production throughput.

- Film uniformity – stable pressure and consistent gas delivery improve coating quality.

- Reduced downtime – valves designed with smooth contours and shorter lengths are easier to maintain and less prone to buildup.

- System longevity – by reducing strain on pumps and other downstream components, high-conductance designs extend the operating life of critical hardware.

These advantages make HC ball valves particularly valuable in advanced deposition methods like ALD, where precise layer control is essential, and in high-volume PVD systems, where efficiency drives profitability. In high-throughput environments, maintaining conductance through larger valve diameters prevents material buildup that can shorten maintenance cycles.

How to Add a High Conductance Valve to your System

Adding a high conductance valve to your system is a valuable investment in long-term performance. You’ll first want to determine whether your application requires a manual or pneumatically actuated valve.

Then, you can reference ANCORP’s high conductance ball valve range to explore available options compatible with your system.

In need of a custom valve? Our technical sales engineers work closely with customers every day, customizing our proven solutions to seamlessly integrate with existing and evolving systems. Reach out to sales@ancorp.com or complete our custom request form to get started today.