Extended Life Ball Valve: ANCORP’s Patented Solution

The ball valve is a desirable isolation valve designed to direct the flow of gases and other materials within a vacuum system. They are reliable and have a variety of advantages over other kinds of isolation valves, especially for shutoff applications. Even with these considerations, several process challenges can arise that affect the lifetime of your valve.

Luckily, ANCORP’s Extended Life stem seal design mitigates these effects and increases the overall lifetime of your system’s ball valves by ten times. Below, we walk you through the issues our customers were experiencing and dive into the changes ANCORP engineers made to make the industry’s leading ball valve.

Table of Contents

Valve Limitations

Choosing the suitable valve to control the flow is paramount in vacuum systems and processes. When selecting the correct valve, various options like gate valves, poppet valves, butterfly valves, pendulum valves, and ball valves often come into consideration.

An unfortunate drawback to many of these options is that internal components are exposed to contaminants during valve actuation. Residual gases can get trapped in these areas, cause virtual leaks, and increase the wear on valve components. These effects can cause costly changes in maintenance schedules and system operation. The ball valve’s simple, straight-through design and ability to perform a self-cleaning function during the ball’s actuation against PTFE seats partially mitigate these effects. However, the performance of traditional ball valves is often plagued by a fundamental issue: leaking.

General Ball Valve Problem

One of the critical problems with traditional ball valves is their susceptibility to leakage. During the actuation of these valves, issues arise due to unstable stems and less-than-optimal stem seal designs. These factors contribute to unwanted leaks, which can be both a nuisance and a financial burden. Leaks not only disrupt system operation but also lead to increased maintenance costs.

That’s where the ANCORP Extended Life ball valve comes into play.

The Solution: ANCORP's Extended Life Ball Valve

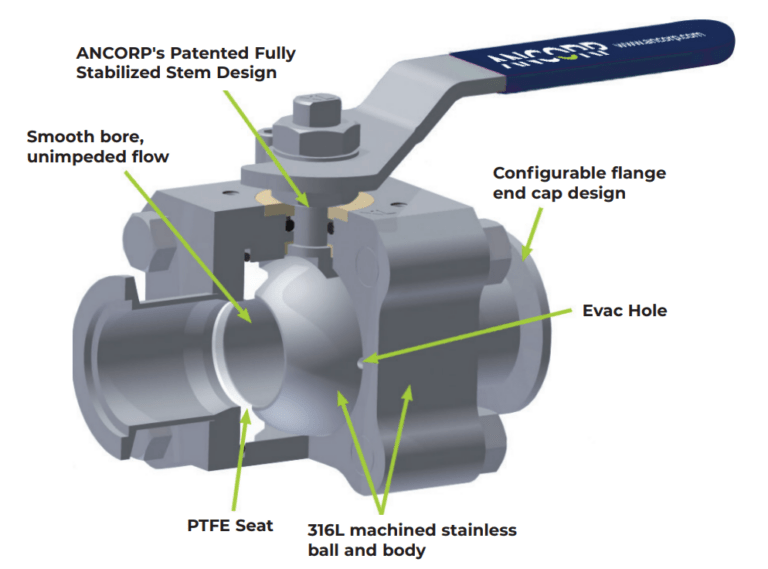

ANCORP’s Extended Life ball valve offers a remarkable solution to the persistent leaking problem in traditional ball valves. Thanks to its innovative design, this valve boasts superior leak control, ensuring that your high vacuum applications run smoothly without the headache of unwanted leaks.

ANCORP engineers took note of the drawbacks in traditional ball valve design and fielded customer requests for a longer-lasting ball valve, particularly when using FFKM O-rings in high-temperature applications. With these benchmarks in mind, they began developing the Extended Life ball valve to provide a much-needed solution. This breakthrough innovation improves upon standard ball valves, adding various updates to bring the best high vacuum ball valve to the industry.

Addressing the Vulnerable Components

Over time, the industry has grappled with various solutions to combat challenges posed by extreme temperatures and harsh process chemistries. However, these solutions often presented their own set of problems. For example, including metallic-bearing materials can lead to process contamination. Valve stem leaks were often addressed by utilizing multiple stem O-rings or a gland packing that can be further compressed into the gland when leaks occur. However, these solutions create more problems. Multiple stem O-rings open can cause virtual leaks, and gland packings are susceptible to extrusion in applications where the packing material will expand due to thermal, chemical, or both effects.

When designing the ANCORP Extended Life ball valve, the top priority was building off the best practices in current designs while addressing their limitations. The result is a breakthrough innovation that boasts superior leak control.

The Game-Changing Developments

The Extended Life patent for ANCORP ball valves is founded upon several key elements that work together to provide the best leak control in the industry. These innovations include utilizing upper and lower PEEK valve stem bearings and an improved valve-body gland design to stabilize the valve stem.

1. Valve Stem Bearing Materials

Metallic bearings are typically created from copper alloys, which are susceptible to corrosion by some process chemistries and may even contaminate a process. By using PEEK components in these areas, the valve is instantly improved in its ability to withstand extreme temperature and exposures to harsh chemicals or byproducts without the risk of contaminating the process.

2. Redesigned Stem Seal

To prevent extrusion and ensure the valve’s longevity, we meticulously redesigned the stem seal. This redesign enhances reliability and bolsters the valve’s performance in challenging environments.

Our redesign of the stem gland was carried out to ensure that a single O-ring would provide a long-lasting high vacuum seal that could operate at high temperatures without the risk of O-ring extrusion, regardless of which O-ring material was used. By carefully engineering the gland area, the O-ring is precisely compressed to maintain the right balance of parameters for a leak-free seal, even when using a high thermal expansion O-ring material, like an FFKM, at high temperatures where extrusion would be a significant concern for previous designs. Moreover, virtual leaks will not occur since only one O-ring seals the valve stem.

All ANCORP ball valves are vacuum rated to 1X10-8 Torr and helium leak rated less than 1X10-9 std. cc/s.

3. Stabilization Mechanism

Stem stabilization was a high-priority goal in the redesign to improve seal reliability. The upper and lower bearings work together to achieve this effect, improving the lateral stabilization of the stem.

The PEEK bearings were precisely located with tight tolerances in critical areas to locate and support the new valve stem. These bearings provide the physical support needed to keep the valve stem accurately located at all times, thereby reducing the wear experienced by the stem O-ring. This simple yet critical alteration contributes to the improved reliability of the stem assembly.

Exploring the Extended Life Ball Valve

These innovations set the Extended Life ball valve apart from the rest by creating the longest-lasting high vacuum ball valve on the market, redefining what’s possible for ball valves in extreme environments. The innovation showcased by our ANCORP engineers never ends, with our newest valve offering taking the standard ball valve to the next level with the highly configurable Multiport Ball Valve.

Dive deeper into the features and specifications of our high vacuum ball valves with patented Extended Life technology or explore our offering of vacuum valves.