Semiconductor

Vacuum And The Semiconductor Industry

Making processes more efficient, reducing down time, and reducing your cost of delay.

The semiconductor industry is entering a new era of innovation driven by increasing energy demands, renewable energy efforts, the internet of things, and accelerating growth in transportation, communication, data processing, artificial intelligence, consumer electronics, and industrial markets. From smartphone logic boards to chips driving autonomous vehicles, ANCORP’s high and ultra-high vacuum products are used in the semiconductor manufacturing processes that help make these innovations possible.

Due to the immense precision and accuracy required during each step of the semiconductor manufacturing process, it is imperative that high vacuum technology be employed to maintain process cleanliness to reduce contamination. Everything from our standard components to our build-to-print custom fabrications are used in the process tools, metrology equipment, and downstream gas abatement systems in semiconductor fabrication facilities that produce integrated circuits, LEDs, solar panels, microelectronics, and more.

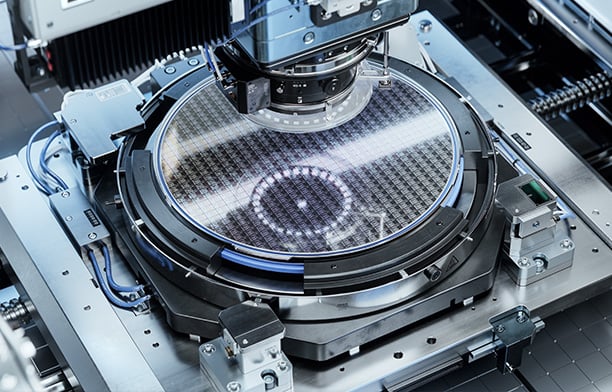

Extreme Ultraviolet (EUV) Lithography

Extreme Ultraviolet (EUV) lithography is a cutting-edge photolithography technology used to pattern the most advanced semiconductor devices, enabling feature sizes below 10 nanometers. Unlike traditional deep ultraviolet (DUV) systems that use 193 nm light, EUV lithography operates at a much shorter wavelength of 13.5 nanometers, which allows for higher resolution and more precise patterning of transistor structures. Due to the high absorption of EUV light by air and most materials, the entire optical path must maintain vacuum. EUV systems rely on reflective optics instead of lenses, using multiple mirrors to guide and focus the EUV light without significant loss. The extreme precision, cleanliness, and stability required for EUV lithography make vacuum system design and integration especially critical to its function.

Vacuum Chambers

In EUV lithography tools, vacuum chambers enclose every stage of the optical path, including the EUV light source, mirror arrays, and the wafer stage. The chambers are often segmented into multiple interconnected volumes, each independently pumped and sealed, to isolate sensitive components and provide better control over environmental conditions. Users can choose from several chamber shapes including spherical, cylindrical, and box based on their application.

ConFlat (CF) Flanges and Fittings

CF components are used throughout EUV systems to connect and seal ports on vacuum chambers with high integrity. CF flanges form leak-tight seals using copper gaskets compressed between knife-edge stainless steel flanges, making them ideal for the vacuum and bake-out conditions required in EUV tools. CF flanges are used to mount diagnostic equipment, optical viewports, pump ports, and various sensor or actuator interfaces.

Rotary Motion Feedthroughs

Rotary feedthroughs are essential in EUV systems for transmitting rotational motion into the vacuum chamber while preserving its sealed environment. They are commonly used in wafer stages, where precise rotational alignment of the wafer is needed during exposure, or in mirror assemblies that require in-situ adjustment. In EUV lithography, the ability to move components without breaking vacuum is critical for both throughput and system uptime, and rotary feedthroughs enable these adjustments with high repeatability.

Scrubber and Abatement Tools in Subfab

Subfabs are critical support areas located beneath the main cleanroom of a semiconductor fabrication facility (fab) and manage the essential utilities and infrastructure that enable these processes. Abatement tools in these environments reduce or eliminate hazardous byproducts, such as toxic gases, particulates, and volatile organic compounds (VOCs), generated during fabrication processes like etching, deposition, and ion implantation. These tools help ensure compliance with environmental regulations, protect worker safety, and maintain cleanroom integrity. Vacuum components such as valves, flanges, and fittings, play a critical role in the efficiency and safety of abatement tools by controlling and isolating process gases, maintaining vacuum integrity, and safely transporting exhaust gases to the abatement units.

Multiport High Vacuum Ball Valve

ANCORP’s multiport valves are well-suited for abatement tools in semiconductor manufacturing due to their corrosion-resistant construction, high-temperature capability, and clean dynamic sealing. Their PTFE valve seats and FKM/FFKM O-rings ensure long-term reliability in harsh chemical environments, while the fully ported ball design minimizes contamination and particulate buildup. With 3-, 4-, and 5-way flow configurations, these valves offer flexible routing for diverting or isolating process gases, making them ideal for efficient integration in abatement systems.

ISO-QF (KF) Flanges and Fittings

The ISO-QF (KF) flange family is best for providing quick, modular connections in rough to high vacuum ranges. KF flanges and fittings are easier to assemble and disassemble, which is ideal for serviceable sections of abatement systems or for prototyping setups where flexibility is needed.

Wafer Handling Load Locks

In semiconductor fabrication, wafer handling load locks are critical subsystems used to transfer wafers between different pressure environments without contaminating the clean vacuum environment or exposing sensitive processes to the atmosphere. They act as sealed transition chambers that isolate the vacuum of processing tools from exposure to air, moisture, and particulates. Wafers are loaded into the load lock at atmospheric pressure, after which the chamber is pumped down to vacuum before the wafers are transferred into the main process chamber. This process protects vacuum integrity, reduces pump-down time, and maintains high throughput in wafer handling operations.

Vacuum Chambers

Vacuum chambers are at the heart of the load lock, forming the structural and functional space where pressure transitions occur. Chambers are fabricated from stainless steel or aluminum to withstand repeated vacuum cycling and to minimize outgassing, which could otherwise introduce contaminants. ANCORP offers spherical vacuum chambers, cylindrical vacuum chambers, and box vacuum chambers for different system configurations.

Vacuum Viewports

Vacuum viewports are another crucial component integrated into the load lock chamber. These are vacuum-compatible transparent windows, made from quartz, sapphire, borosilicate glass, and other materials, mounted with flanges to ensure leak-tight sealing. In a load lock, viewports allow operators or automated systems to visually inspect the wafer position or orientation without breaking vacuum. They may also serve as access points for optical systems such as laser interferometers, cameras, or IR sensors used for wafer alignment and detection.

ConFlat (CF) Flanges and Fittings

CF flanges and fittings are a standard type of flange system used in load lock systems and other vacuum environments in semiconductor manufacturing. These components create ultra-high vacuum (UHV) seals using a metal-to-metal connection, typically involving a stainless steel flange with a knife-edge and a soft copper gasket. When the flange is tightened, the knife-edge bites into the copper, forming a gas-tight, leak-free seal capable of withstanding high temperatures and repeated vacuum cycling.

Rotary Motion Feedthroughs

Rotary feedthroughs allow rotational motion to be transmitted from the external environment into the vacuum chamber without compromising the vacuum seal. In wafer handling, rotary feedthroughs can be used to rotate wafer stages or end effectors of robotic arms, especially when the wafer needs to be aligned with specific orientations for transfer or processing.

Etching Tools

Etching tools are used to remove material from the surface of a wafer to define patterns in films or layers deposited during earlier process steps. This process is essential for creating the intricate circuit structures found in integrated circuits. Etching can be performed using wet (chemical) or dry (plasma-based) methods, though modern fabrication predominantly uses dry etching due to its higher precision and anisotropy (directional control). Dry etching tools typically involve reactive ion etching (RIE), where a plasma of reactive gases is used to selectively etch exposed areas of the wafer, guided by a patterned mask. These tools operate under vacuum and allow fine control over parameters like gas flow, RF power, pressure, and etch time to achieve high aspect ratio features with minimal damage.

Vacuum Chambers

In both dry etching (like Reactive Ion Etching, RIE) and plasma etching systems, vacuum chambers provide the core environment where plasma physics, gas-phase chemistry, and wafer-surface reactions all converge in a tightly controlled manner. Its design directly determines process precision, repeatability, and yield, and ANCORP provides several shape options including spherical, cylindrical, and box to optimize your design.

Vacuum Angle Valves

Angle valves are commonly used to manage the flow of gases and maintain vacuum isolation within critical parts of the system. Their L-shaped configuration allows for compact integration into the vacuum plumbing between the etch chamber, pumping lines, and gas delivery paths.

Vacuum Pendulum Valves

Unlike standard gate or poppet valves, pendulum valves offer precise pressure regulation capabilities, which are essential for stabilizing chamber pressure during plasma-based etch processes. They are typically mounted at the base of the process chamber and can quickly swing open or closed with minimal particle generation.

Flanges and Fittings

Flanges and fittings play a foundational role in the physical construction and performance of etching tools by ensuring that vacuum lines, gas lines, and process chambers are securely and leak-tightly connected. In the vacuum subsystems, CF flanges, using copper gaskets, or ISO flanges, using elastomer O-rings, are used to seal components like valves, viewports, and pumps to the chamber while maintaining high vacuum integrity.

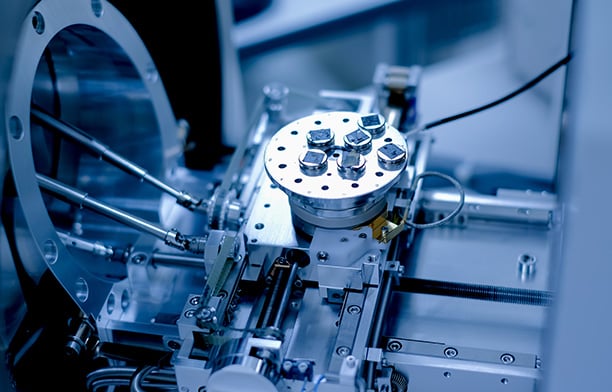

Scanning Electron Microscopy

Scanning Electron Microscopy (SEM) is a foundational inspection and metrology tool in semiconductor processing, providing nanometer-scale imaging of surface structures. A focused electron beam scans the sample, and secondary electrons emitted from the surface are detected to generate high-resolution images. SEM is critical for measuring critical dimensions, evaluating sidewall profiles after etching, detecting defects, and monitoring process drift. To maintain beam focus and minimize electron scattering, SEM systems require a vacuum environment within both the electron column and sample chamber, which is maintained and controlled through several critical vacuum components.

Vacuum Chambers

An SEM system contains two vacuum chambers: the electron column and the sample chamber. The electron column houses the electron source, lenses, and beam path to preserve beam coherence, minimize scattering, and protect the cathode. It is constructed as a sealed vacuum envelope, often supported by its own dedicated pumping system. The sample chamber contains the specimen stage and detectors. Maintaining a stable vacuum in the sample chamber is critical for imaging fidelity, minimizing contamination, and protecting downstream optics.

Vacuum Gate Valves

Gate valves are installed between the sample chamber and the pumping system. They provide isolation during sample loading/unloading, allowing the chamber to be vented and re-pumped without exposing the entire vacuum system. Their large orifice design minimizes conductance loss when open, maintaining rapid pump down and consistent chamber base pressures when closed.

Vacuum Angle Valves

Angle valves regulate vacuum line conductance with a compact, right-angle flow path, reducing footprint while maintaining high conductance rates. In SEM systems, they are often used in roughing lines, vent lines, or as isolation points for subcomponents like load locks or cryo pumps.

Flanges and Fittings

Flanges connect pumps, valves, gauges, and chamber ports. CF flanges use a knife-edge seal against a copper gasket, providing bakeable, UHV-tight joints ideal for the electron column and critical sample areas. KF fittings, which use an O-ring and clamp, are employed in less demanding zones such as backing lines, allowing rapid assembly and disassembly during maintenance or upgrades.