Research and Development

Empowering Scientific Advancement

From nuclear and particle physics to quantum research, optics, and materials science, breakthroughs across disciplines rely on precision-controlled vacuum environments.

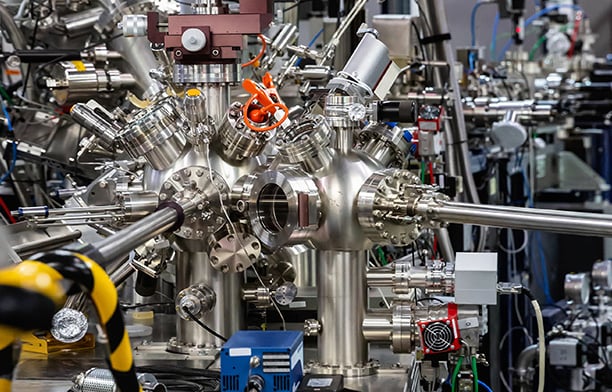

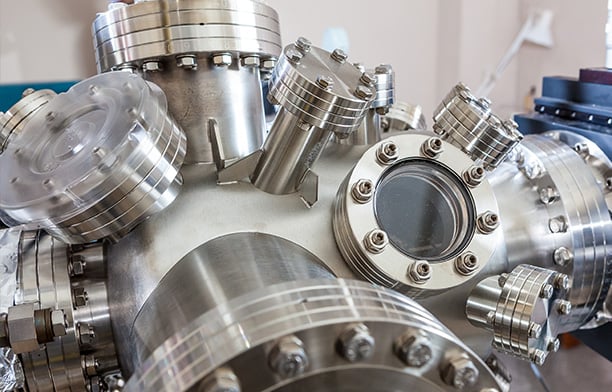

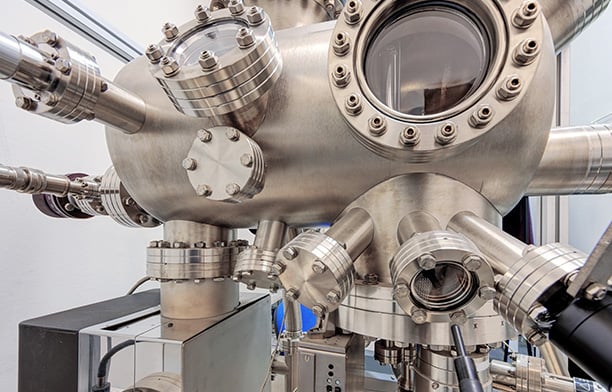

High and ultra-high vacuum (UHV) systems are essential for maintaining the clean, low-pressure, and often temperature-controlled conditions needed to observe and manipulate matter at the atomic and subatomic levels. Whether isolating qubits in quantum computing, depositing thin films for next-generation electronics, or simulating interstellar environments, researchers depend on robust and reliable vacuum technology to enable discoveries that drive the future of energy, healthcare, security, transportation, and advanced materials.

ANCORP supplies durable vacuum chambers, valves, and hardware to leading research institutions around the world. Our components are engineered to perform in the most demanding scientific environments and are trusted by labs working at the forefront of innovation.

As the landscape of science and technology continues to evolve, ANCORP is prepared to partner with researchers to meet their unique needs and challenges. With a commitment to helping our customers solve problems, we stand ready to provide researchers with the solutions they need through products that facilitate the discoveries of tomorrow. ANCORP has a long-standing history of supporting advancements in areas ranging from synchrotrons and beamlines to environmental sustainability efforts and space exploration.

Contact us for more information or request a quote for a custom-fabricated component.

Physics Research

Vacuum systems are indispensable in experimental physics, providing controlled environments free from atmospheric interference. In particle and nuclear physics, beamlines and accelerators depend on ultra-high vacuum (UHV) components to maintain particle integrity and prevent scattering. In quantum physics, vacuum isolation allows for trapping and cooling atoms, manipulating qubits, and studying quantum behavior without interference from air molecules. For example, ANCORP designed a spherical UHV chamber for Brookhaven National Laboratory’s high-voltage polarized electron gun, part of the world’s first fully polarized Electron-Ion Collider, where maintaining extreme vacuum conditions was critical to protecting sensitive components and enabling accurate beam generation. Quantum optics and quantum computing also rely on vacuum systems to isolate atoms and photons from air molecules and thermal noise, enabling precise measurements and manipulation at the quantum level.

Vacuum Chambers

Vacuum chambers are essential for creating ultra-high vacuum (UHV) environments in experiments like particle acceleration, quantum optics, and atomic trapping. ANCORP’s vacuum chambers are designed to deliver exceptional performance in high vacuum (HV) and UHV environments, with customizable configurations and durable construction using premium stainless steel and aluminum.

Vacuum Gate Valves

VAT gate valves allow isolation of different sections within a vacuum system without compromising overall vacuum integrity. These valves are crucial in high-energy physics setups to maintain vacuum conditions during maintenance or sample changes.

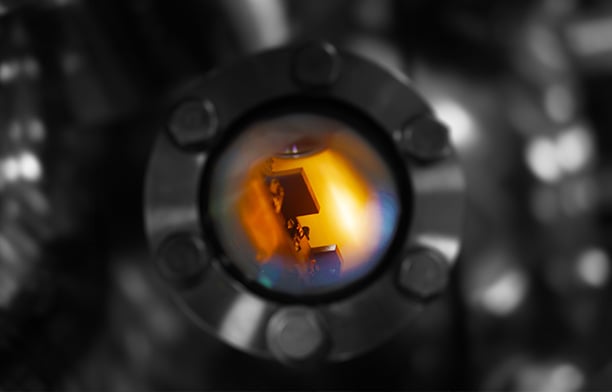

Vacuum Viewports

Vacuum viewports provide optical access to vacuum chambers for laser alignment, spectroscopy, or observation. High-performance optical viewports are vital in quantum physics research to ensure optical clarity under vacuum conditions.

UHV & Synchrotron

Synchrotron and free-electron laser (FEL) facilities demand some of the most stringent vacuum environments in scientific research. At their core are ultra-high vacuum (UHV) systems that allow electrons to accelerate to near-light speeds before emitting synchrotron radiation. This radiation travels down beamlines used in a wide range of fields, from structural biology and photon science to nuclear and condensed matter physics.

Maintaining UHV is critical for preserving beam quality and photon intensity. Even trace gas molecules can scatter or absorb photons, degrading experimental resolution. At beamlines such as those at the Advanced Photon Source (APS) and DESY, every component, valves, flanges, viewports, and chambers, must meet strict vacuum, alignment, and vibration tolerance standards.

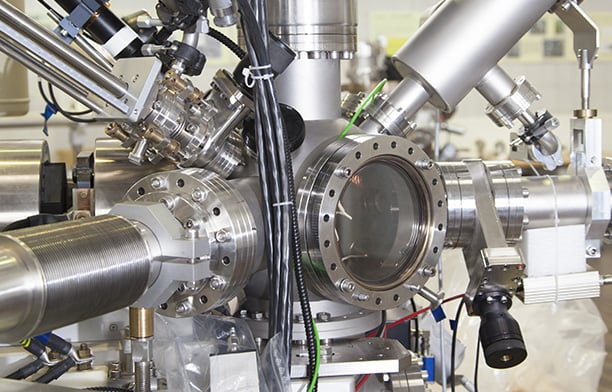

Multiport Cluster Flanges

ANCORP’s multiport cluster flanges enable integration of beam diagnostics, manipulators, and optical ports into compact assemblies. Multiport cluster flanges are UHV-compatible and streamline beamline setups while maintaining strict vacuum integrity.

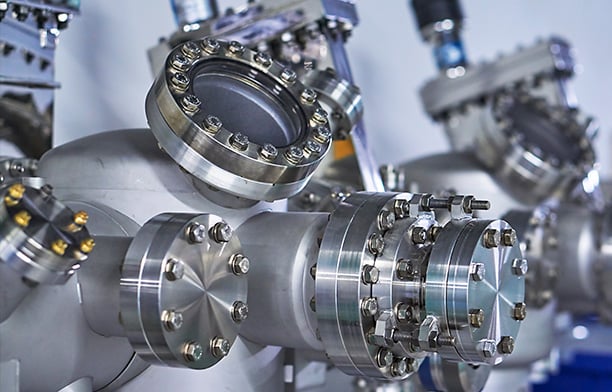

ConFlat (CF) Flanges and Fittings

ConFlat (CF) flanges and fittings feature all-metal seals and offer unmatched long-term stability in UHV environments. ANCORP’s CF hardware includes cross, tee, nipple, and half-nipple varieties for flexible system integration.

Vacuum Viewports

ANCORP’s optical-grade viewports, including fused silica and sapphire options, support high-resolution beamline monitoring and diagnostics. Specialized UV- and IR-grade variants enable studies across the full spectrum of synchrotron radiation.

Materials Science & Surface Analysis

Vacuum technology plays a foundational role in materials science, especially in the characterization and fabrication of advanced materials. Thin-film deposition techniques, such as chemical vapor deposition (CVD) and physical vapor deposition (PVD), require vacuum environments to prevent contamination and ensure uniform layer formation. Surface analysis methods like X-ray photoelectron spectroscopy (XPS), Auger electron spectroscopy (AES), and reflection high-energy electron diffraction (RHEED) depend on vacuum conditions to analyze material surfaces at the atomic level. UHV conditions are critical to observe atomic-level changes without interference from atmospheric gases, enabling breakthroughs in coatings, semiconductors, and nanomaterials.

Vacuum Chambers

Vacuum chambers are used in techniques like X-ray photoelectron spectroscopy (XPS) and Auger electron spectroscopy (AES) to analyze material surfaces at the atomic level. These chambers maintain contaminant-free environments essential for accurate surface analysis.

Vacuum Ball Valves

ANCORP’s high vacuum ball valves enable precise control of the flow of chemicals, gases, and other substances in vacuum systems during processes like metal-organic chemical vapor deposition (MOCVD) and ion-beam deposition (IBD). Their design ensures minimal contamination and consistent vacuum conditions.

Rotary Feedthroughs

Rotary feedthroughs allow rotation of samples or components within a vacuum chamber without compromising vacuum integrity. They are essential in applications requiring precise angular positioning during material processing.

Chemistry & Catalysis Research

In chemical research, vacuum systems are used to study reactions, characterize compounds, and control environments for sensitive measurements. Mass spectrometry, for example, requires high vacuum to accurately analyze ionized molecules. Surface chemistry and catalysis experiments often involve exposing materials to gases under controlled vacuum conditions to study reaction mechanisms. These systems help eliminate background gases and allow researchers to monitor chemical processes on a molecular level, aiding in the development of new catalysts and materials.

Vacuum Leak Valves

VAT leak valves allow precise introduction of very small gas flows into a vacuum system, crucial for studying reaction mechanisms and kinetics in catalysis research. They enable controlled environments for surface chemistry experiments.

Vacuum Viewports

Vacuum viewports provide visual and optical access to chemical reactions occurring within vacuum chambers, facilitating real-time monitoring and analysis of processes like gas-phase reactions.

ISO-QF (KF) Flanges and Fittings

ISO-QF (KF) flanges and fittings offer quick and reliable connections in vacuum systems, commonly used in laboratory setups for their ease of assembly and flexibility in configuring experimental apparatus.

Engineering & Applied Research

Across various engineering disciplines, vacuum systems support the development and testing of next-generation technologies. Microelectromechanical systems (MEMS), lasers, and semiconductor devices often require fabrication and testing in vacuum to ensure precision and performance. Vacuum systems are also used in laser ablation, tribology, and energy storage research, such as in battery testing, where they prevent oxidation, enable controlled reactions, and simulate extreme operating conditions. For instance, the University of Oxford utilizes vacuum chambers to assess the influence of gases and vacuum on precise laser processing within environment control chambers.

Multiport Cluster Flanges

Multiport cluster flanges are useful in laser systems, MEMS testing, or tribology experiments, where multiple monitoring devices (e.g., photodetectors, pressure sensors) and tools (feedthroughs, actuators) are used.

Electrical Feedthroughs

Electrical feedthroughs facilitate the transmission of electrical signals or power into vacuum chambers, essential for operating sensors, heaters, or other electronic components within the vacuum environment.

Vacuum Chambers

Vacuum chambers serve as controlled environments for testing and developing technologies like microelectromechanical systems (MEMS), lasers, and semiconductor devices. These chambers are tailored to specific research needs, ensuring accurate and repeatable results.

Astrophysics & Space Sciences

In laboratory astrophysics, vacuum systems are critical for simulating space-like environments to study cosmic phenomena under controlled conditions. Researchers replicate interstellar and planetary environments by using vacuum chambers to examine low-temperature plasmas, dust grain behavior, radiation interactions, and chemical processes occurring in space. These simulations help scientists better understand the formation of stars, planetary atmospheres, and cosmic dust evolution. Ultra-high vacuum, cryogenic vacuum setups are commonly used to mimic the interstellar medium or planetary surfaces, allowing precise studies of photon and ion interactions with gases, ices, and minerals under vacuum conditions. Such experiments bridge observational astronomy with experimental validation and are vital for interpreting data from telescopes and space missions.

Vacuum Chambers

Vacuum chambers are used to simulate space-like environments for studying cosmic phenomena under controlled laboratory conditions. These chambers are used to examine low-temperature plasmas, dust grain behavior, and radiation interactions.

ConFlat (CF) Flanges and Fittings

ConFlat (CF) flanges and fittings provide leak-tight, metal-sealed connections suitable for ultra-high vacuum applications, essential in experiments replicating interstellar conditions.

Biological & Environmental Sciences

While not traditionally associated with vacuum systems, biological and environmental sciences increasingly benefit from high and ultra-high vacuum (UHV) technologies. Cryo-electron microscopy (Cryo-EM), for example, relies on vacuum conditions to maintain vitrified biological samples and achieve high-resolution imaging at cryogenic temperatures. These imaging techniques enable near-atomic-level visualization of viruses, proteins, and other macromolecules critical to biomedical research.

Environmental studies may use vacuum chambers to simulate extraterrestrial atmospheres, such as those on Mars or the Moon, or to study aerosol dynamics, gas-phase reactions, and dust behavior in clean, low-pressure conditions. For instance, researchers at Utah State University use vacuum chambers to analyze the effects of lunar regolith on materials, simulating real-world space conditions that future landers and habitats must endure.

Vacuum Chambers

Vacuum chambers are utilized in cryo-electron microscopy (Cryo-EM) to maintain sample integrity and achieve high-resolution imaging of biological specimens at cryogenic temperatures.

Vacuum Feedthroughs

Vacuum feedthroughs enable integration of sensors, electrical connections, or fluid lines into vacuum systems, supporting complex experimental setups in biological research.

Vacuum Filters

Vacuum filters prevent contamination and protect vacuum pumps by filtering out particles and vapors, ensuring clean vacuum conditions necessary for sensitive biological and environmental experiments.